It acts as a protective device, both to protect objects such as ground staff from being hit by the whirling blades, and to protect the blades from damage during such an impact. It provides acoustic shielding which, together with the reduced energy waste, significantly cuts noise emissions from the propeller.

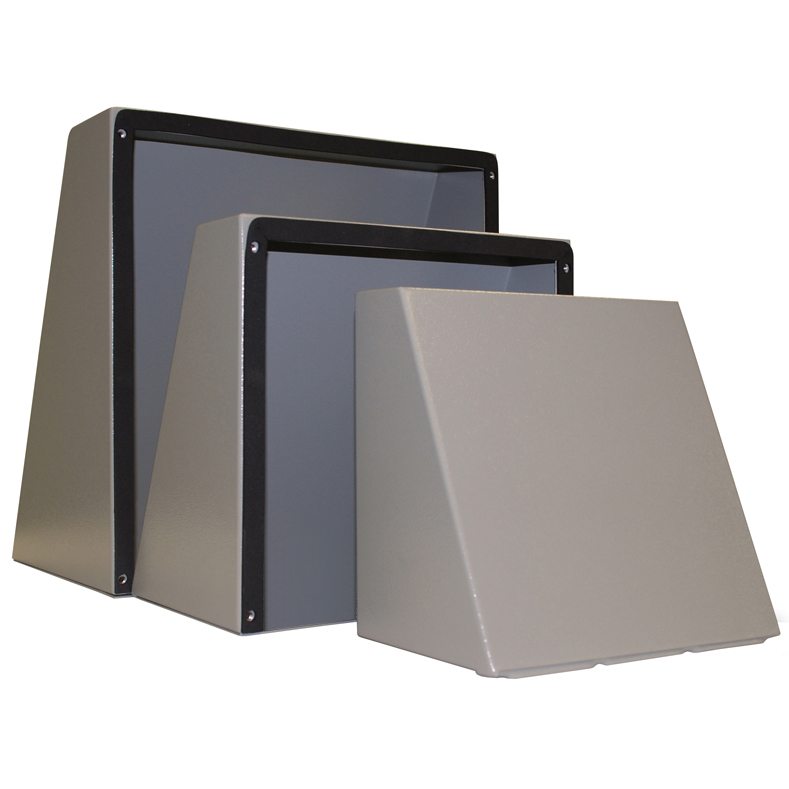

#Fan shroud free#

Because of this, the fan can either be used to provide increased thrust and aircraft performance, or be made smaller than the equivalent free propeller. This reduces the aerodynamic losses or drag, thus increasing the overall efficiency of the fan. Principally, it reduces the vortices created by air flowing round the ends of the blades. It must be made rigid enough not to distort under flight loads nor touch the blades as they turn. The duct or shroud is an aerodynamic ring which surrounds the fan and closely fits the blade tips. The blades may be of fixed or variable pitch. The Rhein Flugzeugbau (RFB) SG 85 had three blades, while the Dowty Rotol Ducted Propulsor had seven. Like any other fan, propeller or rotor, a ducted fan is characterised by the number of blades. Lastly, when at high angles of attack, the shroud can stall and produce high drag.Ī ducted fan has three main components the fan or propeller which provides thrust or lift, the duct or shroud which surrounds the fan, and the engine or motor which powers the fan.

By varying the cross-section of the duct the designer can advantageously affect the velocity and pressure of the airflow according to Bernoulli's principle.ĭrawbacks include increased weight due to the added structure of the shroud, a need for precision in tolerances of blade-tip to shroud clearance, a need for better vibration control compared to free-air propellers, and complex duct design requirements. The shroud offers good protection to ground personnel from accidentally contacting the spinning blades, as well as protecting the blades themselves from external debris or objects. Ducted fans are quieter, and offer good opportunities for thrust vectoring. The duct increases thrust efficiency by up to 90% in some cases, in comparison to a similar-sized propeller in free air. The high-bypass turbofan engines used on many modern airliners is an example of a very successful and popular use of ducted fan design. ĭucted fans are used for propulsion or direct lift in many types of vehicle including aeroplanes, airships, hovercraft, and powered lift VTOL aircraft. ( VTOL) applications it is also known as a shrouded rotor.

When used in vertical takeoff and landing Other terms include ducted propeller or shrouded propeller. (I am still intrigued by an approach that would remove the mounting straps from the block perhaps an experienced tech will comment).In aeronautics, a ducted fan is a thrust-generating mechanical fan or propeller mounted within a cylindrical duct or shroud. BTW, the engineers at GM who designed the fan shroud this way should be criminally prosecuted for crimes agains humanity. Seven push pins in the radiator cover, two bolts and four push pins on the shroud itself (plus one in the TCM that attaches to there shroud). As noted, the upper half of the radiator shroud must come out - that's the easy part. I don't trust myself to not gouge the radiator when removing the fan and shroud (which come out together), so I slipped a piece of cardboard ink between. But IIRC it is 44 mm, and a dedicated air hammer fan nut tool saves all kinds of hassle and time. There are a variety of ways to get the fan nut off. Pulling it back up is far less time consuming than trying to fish it out from below. Do tape some twine to your wrench, for dropping it a few times is inevitable. Don't try to get a ratchet and socket on these lower bolts, for the lower radiator shroud won't give enough room (unless, perhaps, you grind a i/4 inch socket shorter and perhaps use a socket cap and gear wrench).

#Fan shroud how to#

And if you know how to remove what I believe is the intercooler pipe flexible boot on the passenger side, that will give very good maneuvering room for that lower passenger side bolt. Careful not to break one of the mounting tits or get the JB Weld out. Fan shroud has "top" indicated on back side it will only bolt up one way. Rubber lip faces in toward the engine and is not bent the other way. Be sure fan shroud rubber ring sits correctly in the lower portion of the radiator shroud before installing the bolts. I started to cross thread the lower passenger side bolt and had to run it through from the back side to clean it all up. Don't tighten bolts until all are started.

You'll need small hands and wire on the bolt to direct them back in. A stubby 13 mm gear wrench will remove the lower bolts on the fan shroud.

0 kommentar(er)

0 kommentar(er)